Wire made of molybdenum, tungsten and tantalum.

Shenzhen Sunrise Metal Industry Co.,Ltd

TEL:0086-0755-27185042

Website:http://www.sunriseta.com

E-Mail:sales@sunriseta.com

Shenzhen Sunrise Metal Industry Co.,Ltd

TEL:0086-0755-27185042

Website:http://www.sunriseta.com

E-Mail:sales@sunriseta.com

Website:http://www.sunriseta.com

E-Mail:sales@sunriseta.com

Whether in lamps, coating equipment or a range of other applications: Thanks to their outstanding material purity and low tolerances, our wires made of molybdenum, tungsten, tantalum, niobium and their alloys guarantee constant high quality. Graphite-coated, etched or electropolished: We will supply our wire with the required surface quality.

Order molybdenum, ML, WVM and tantalum wires directly from our online shop: http://www.sunriseta.com

In addition to pure molybdenum, tungsten, niobium and tantalum, we also supply wires made of a variety of alloys:

- Molybdenum-lanthanum (ML) provides excellent performance due to its high ductility, creep resistance and recrystallization temperature.

- Tungsten-rhenium (WRe) shows high ductility.

- Molybdenum-tungsten (MoW) provides particularly high corrosion resistance against zinc.

- Grain-stabilized tungsten (WVM) offers especially high dimensional stability and possesses excellent corrosion resistance against many molten metals.

In addition to pure molybdenum, tungsten, niobium and tantalum, we also supply wires made of a variety of alloys:

- Molybdenum-lanthanum (ML) provides excellent performance due to its high ductility, creep resistance and recrystallization temperature.

- Tungsten-rhenium (WRe) shows high ductility.

- Molybdenum-tungsten (MoW) provides particularly high corrosion resistance against zinc.

- Grain-stabilized tungsten (WVM) offers especially high dimensional stability and possesses excellent corrosion resistance against many molten metals.

Wires as fine as 0.015 mm.

We supply fine wires made of molybdenum and tungsten. These can be as fine as 0.015 millimeters.

Fine tungsten wire is used, for example, in halogen lamps, incandescent lamps and fluorescent lamps. When used in halogen lamps in vehicle headlamps, our wire excels due to its freedom from fissures, outstanding surface quality, very low diametric tolerance and stable mechanical properties.

Almost invisible, our fine tungsten wires heat the windshields of modern vehicles. In this application, the low tolerance ranges required for electrical resistance and the high surface quality of our wires are particularly important.

Among its other applications, fine molybdenum wire is used as support wire in incandescent lamps and core wire in the manufacture of lamp filaments

High capacity. Optimum quality. Your strong partner.

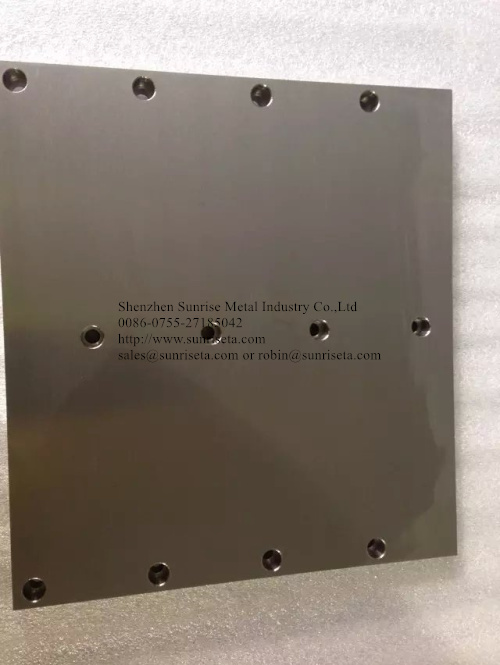

Thanks to our high capacities, we can manufacture even very large quantities of molybdenum sheets without difficulty. Thanks to our state-of-the-art equipment and many years of experience in the field of powder metallurgy, we can guarantee that you receive top quality - in every molybdenum sheet we supply.

Do you have any very special requirements? For us, that's not a problem: As a specialist in the field of refractory metals, we can adapt the tensile strength and surface properties of our sheets to meet your specific needs. Just contact us!

Thanks to our high capacities, we can manufacture even very large quantities of molybdenum sheets without difficulty. Thanks to our state-of-the-art equipment and many years of experience in the field of powder metallurgy, we can guarantee that you receive top quality - in every molybdenum sheet we supply.

Do you have any very special requirements? For us, that's not a problem: As a specialist in the field of refractory metals, we can adapt the tensile strength and surface properties of our sheets to meet your specific needs. Just contact us!

A single source for all your needs.

We handle every stage in the manufacture of our molybdenum sheets in-house. From the raw materials through to the finished product. This ensures that you benefit from high-quality at all times.

We handle every stage in the manufacture of our molybdenum sheets in-house. From the raw materials through to the finished product. This ensures that you benefit from high-quality at all times.