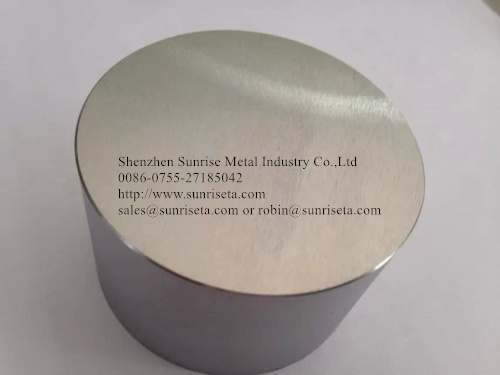

Hafnium (Hf) Sputtering Targets

Shenzhen Sunrise Metal Industry Co.,Ltd

TEL:0086-0755-27185042

Website:http://www.sunriseta.com

E-Mail:sales@sunriseta.com

Specifications

| (2N) 99% Hafnium Sputtering Target | Request | |

| (2N5) 99.5% Hafnium Sputtering Target | Request | |

| (3N) 99.9% Hafnium Sputtering Target | Request | |

| (3N5) 99.95% Hafnium Sputtering Target | Request | |

| (4N) 99.99% Hafnium Sputtering Target | Request | |

| (5N) 99.999% Hafnium Sputtering Target |

Properties

Molecular Weight 178.49 Appearance Silver Melting Point 2227°C Boiling Point 4602°C Density 13.31 g/cm3 Thermal Expansion (25 °C) 5.9 µm·m-1·K-1 Poisson Ratio 0.37 Vickers Hardness 1760 MPa Young's Modulus 78 GPa Tensile Strength N/A Thermal Conductivity 0.230 W/cm/K @ 298.2 K Electronegativity 1.3 Paulings Specific Heat 0.035 Cal/g/K @ 25 °C Heat of Vaporization 155 K-Cal/gm atom at 4602°C

| Molecular Weight | 178.49 |

|---|---|

| Appearance | Silver |

| Melting Point | 2227°C |

| Boiling Point | 4602°C |

| Density | 13.31 g/cm3 |

| Thermal Expansion | (25 °C) 5.9 µm·m-1·K-1 |

| Poisson Ratio | 0.37 |

| Vickers Hardness | 1760 MPa |

| Young's Modulus | 78 GPa |

| Tensile Strength | N/A |

| Thermal Conductivity | 0.230 W/cm/K @ 298.2 K |

| Electronegativity | 1.3 Paulings |

| Specific Heat | 0.035 Cal/g/K @ 25 °C |

| Heat of Vaporization | 155 K-Cal/gm atom at 4602°C |

Material Type Hafnium Symbol Hf Atomic Weight 178.49 Atomic Number 72 Color/Appearance Gray Steel, Metallic Thermal Conductivity 23 W/m.K Melting Point (°C) 2,227 Coefficient of Thermal Expansion 5.9 x 10-6/K

Theoretical Density (g/cc) 13.09 Z Ratio 0.36 Sputter DC Max Power Density

(Watts/Square Inch) 50 Type of Bond Indium Export Control (ECCN) 1C231

| Material Type | Hafnium |

| Symbol | Hf |

| Atomic Weight | 178.49 |

| Atomic Number | 72 |

| Color/Appearance | Gray Steel, Metallic |

| Thermal Conductivity | 23 W/m.K |

| Melting Point (°C) | 2,227 |

| Coefficient of Thermal Expansion | 5.9 x 10-6/K |

| Theoretical Density (g/cc) | 13.09 |

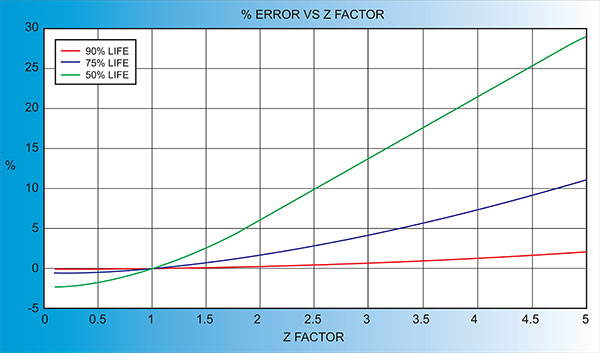

| Z Ratio | 0.36 |

| Sputter | DC |

| Max Power Density (Watts/Square Inch) | 50 |

| Type of Bond | Indium |

| Export Control (ECCN) | 1C231 |

Z-Factors

Empirical Determination of Z-Factor

Unfortunately, Z Factor and Shear Modulus are not readily available for many materials. In this case, the Z-Factor can also be determined empirically using the following method:

- Deposit material until Crystal Life is near 50%, or near the end of life, whichever is sooner.

- Place a new substrate adjacent to the used quartz sensor.

- Set QCM Density to the calibrated value; Tooling to 100%

- Zero thickness

- Deposit approximately 1000 to 5000 A of material on the substrate.

- Use a profilometer or interferometer to measure the actual substrate film thickness.

- Adjust the Z Factor of the instrument until the correct thickness reading is shown.

Another alternative is to change crystals frequently and ignore the error. The graph below shows the % Error in Rate/Thickness from using the wrong Z Factor. For a crystal with 90% life, the error is negligible for even large errors in the programmed versus actual Z Factor.

NOTE: This is an Export Controlled Material. Restrictions may apply.

没有评论:

发表评论